When it comes to industrial processes, durability and efficiency are critical. Successful

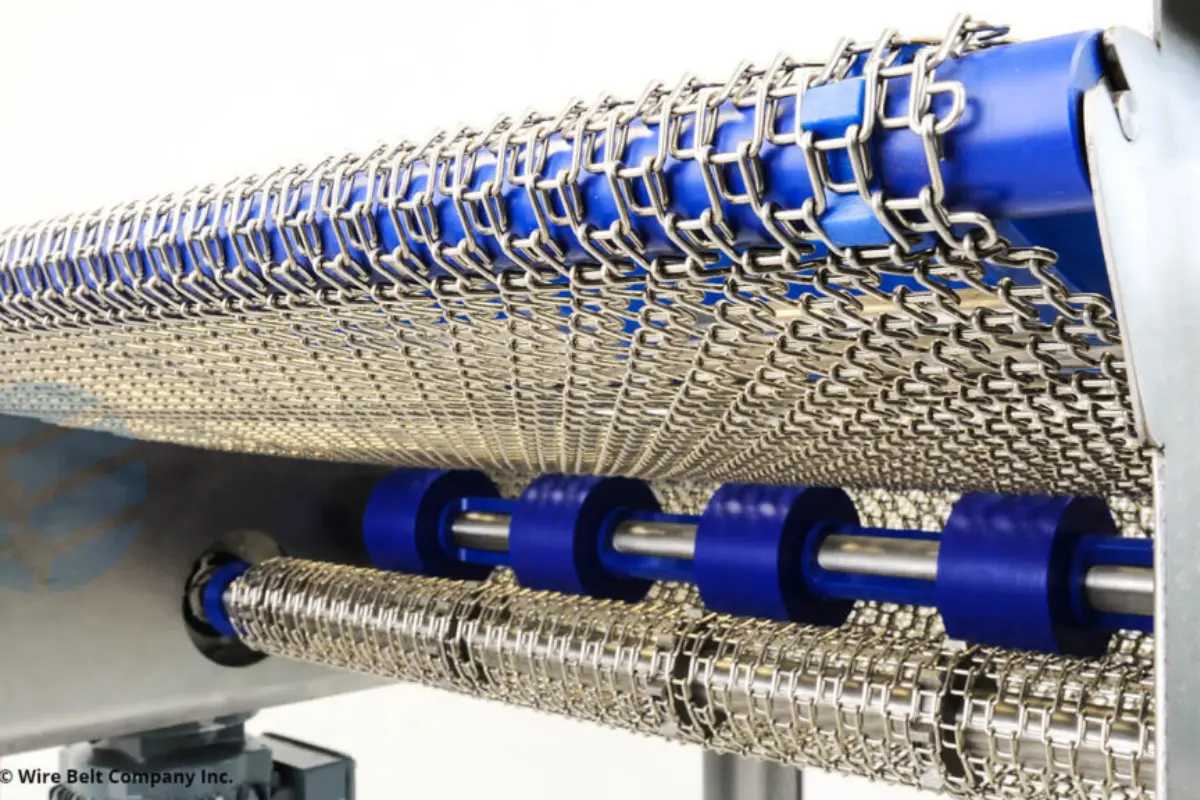

operations in manufacturing, food processing, and logistics depend on the smooth flow of goods. The conveyor belt is a widely used yet essential element at the center of this smooth movement. compact-grid stainless steel conveyor belts also stand out as a superior option in terms of performance and reliability.

Conveyor belts with compact grids are frequently used in material handling applications. It has a design of tightly spaced, tiny-diameter rods or connections that resemble a grid. The materials used to make these rods or links are usually thermoplastic or metal.

Heavy loads can be handled by the grid design because of its high strength and longevity, even though the rods or links have a small diameter.

The closely spaced grid design produces a smooth surface free from the possibility of snagging or catching.

The Compact-Grid belt is ideal for applications where cleanliness is essential, like the food processing or pharmaceutical sectors, because it is simple to clean and maintain.

Compact-grid conveyor belts are adaptable and have various uses in food processing, packaging, automotive, and other industries.

Recognizing The Stainless Steel Conveyor Belt

Conveyor belts are the latest advancement in conveyor technology. They are long-lasting and carefully designed to provide many benefits that dramatically increase operational efficiency.

Compact Design: As stated by the name, the Compact-Grid design maximises the effective conveyance area with precisely constructed, closely spaced links. Because of its compactness, even the tiniest components can be transported without difficulty or chance of clogs or misalignment.

Stainless Steel Construction: Using stainless steel as the main component provides unmatched strength and corrosion resistance. This functionality is essential in sectors like food processing and pharmaceuticals, where strict standards for cleanliness and hygiene are required.

Customisability: It takes flexibility to meet a range of operating needs. Because compact-grid stainless steel conveyor belts are so extensively customisable, customised solutions that match specific workflows and spatial restrictions are possible.

Enhanced Performance: Compact-Grid belts’ unique design minimises downtime and maximises throughput by ensuring steady, smooth movement. Increased productivity leads to increased profitability in the end.

Utilisations In All Sectors: Compact-grid stainless steel conveyor belts are versatile and can be used in various industries.

Food Preparation: Compact-grid belts uphold strict hygiene standards and preserve product integrity from baking to freezing. They are perfect for safely and effectively transporting perishable foods because of their non-porous surface and simplicity of washing.

Automotive Manufacturing: Accuracy and dependability are critical in the automotive industry. Compact-grid belts make transporting parts smoothly throughout the assembly process more accessible, guaranteeing efficient operations and upholding strict quality standards.

Pharmaceuticals: It is imperative to ensure the purity and integrity of products during the production process. The best option is to use compact-grid stainless steel conveyor belts, which create a clean, hygienic environment to move delicate goods.

Benefits Of Stainless Steel Conveyor Belts

Conveyor belts of stainless steel conveyor belts are employed in many sectors for several reasons.

Corrosion Resistance: Because stainless steel resists corrosion so well, it can be used in settings where harsh materials, chemicals, or moisture are frequently present. The conveyor belt’s endurance and durability are ensured by its resistance to corrosion, which lowers maintenance costs and downtime.

Cleanliness & Hygiene: Conveyor belts made of stainless steel are highly suitable for businesses where hygienic practices are crucial, like food processing, pharmaceuticals, and medical equipment, as they are simple to clean and sterilise. Stainless steel’s flat surface keeps impurities and bacteria from building up, guaranteeing product safety and legal compliance.

Resistance To High Temperatures: Conveyor belts made of stainless steel are appropriate for thermal processes such as baking, drying, and heat treatment because they can tolerate high temperatures. They retain their structural integrity and functionality even at high temperatures, guaranteeing dependable operation under challenging conditions.

Stainless steel is renowned for its strength and resilience, offering superior load-bearing capability and mechanical wear and tear resistance. Conveyor belts made of stainless steel are appropriate for heavy-duty industrial, mining, and automotive uses.

Customisation Options: The width, length, thickness, and surface texture of stainless steel conveyor belts can all be adjusted to match the demands of a particular application. Thanks to its adaptability, the conveyor system can be customised to fit different production processes and layouts.

Conveyor Technology: A Look Ahead

Conveyor technology plays a more and more critical role as industries change and needs rise. Conveyor belts made of compact-grid stainless steel offer an early look at this vital piece of technology. By prioritising efficiency, durability, and customisability, they facilitate increased production and operational excellence in various industries.

In summary, using compact-grid stainless steel conveyor belts demonstrates a dedication to efficiency and innovation. Industries may achieve sustainable development and success by optimising their processes, maintaining the highest quality standards, and investing in these state-of-the-art solutions.

![10 Best Bags for Nurses | Personal Recommendation [2023] 4 Best Bags For Nurses Reviews in 2021](https://knowworldnow.com/wp-content/uploads/2022/12/Best-Bags-For-Nurses-Reviews-in-2021.webp)

![F95Zone Games - The Ultimate Guide for 2021 [F95Z Guide] 8 F95Zone Games](https://knowworldnow.com/wp-content/uploads/2021/07/ArTtW5LrK3b-z-0-y-637f48d86203817a9042a857.webp)