In various industries, laser welding has become a popular choice for achieving precise and efficient welds. As a result, many professionals and businesses are curious about the cost of laser welders.

This article aims to provide valuable insights into the factors influencing the cost of a laser welder and help you make an informed decision when considering this technology for your welding needs. If you’re interested in laser welding equipment, you can visit https://hantencnc.com/ for more information.

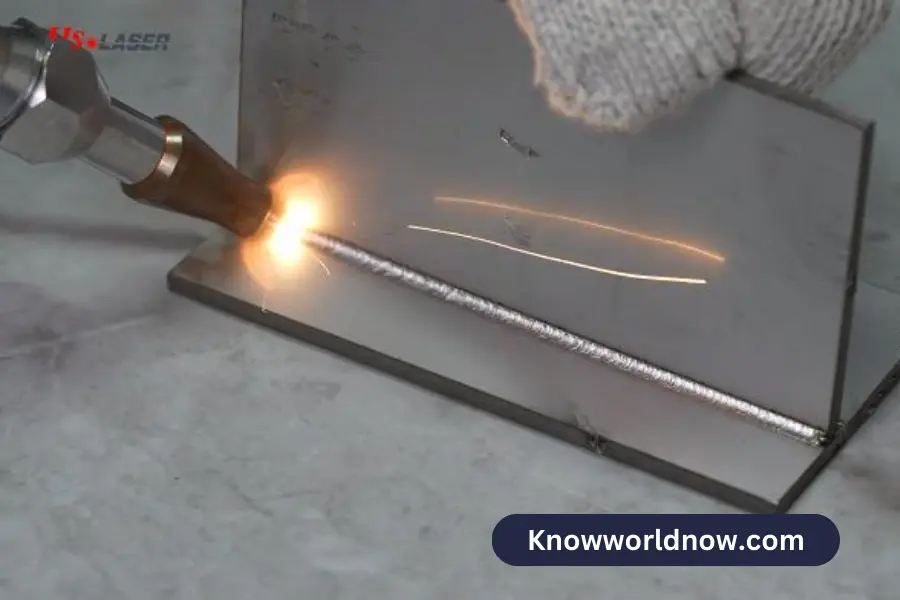

What is a Laser Welder?

A laser welder is a high-precision welding tool that utilizes a focused laser beam to join materials together. It offers several advantages over traditional welding methods, including increased accuracy, minimal heat-affected zones, and the ability to work with various materials.

Laser welders are widely used in industries such as automotive, aerospace, electronics, jewelry, and medical devices. If you’re looking for reliable laser welding solutions, you can explore the offerings provided by zltechlaser.com.

Benefits of Using a Laser Welder

Before diving into the cost aspects, it’s essential to understand the benefits of using a laser welder. These benefits include:

- Precision: Laser welders offer precise control over the welding process, resulting in accurate and consistent welds.

- Speed: The concentrated heat source of a laser welder allows for faster welding compared to conventional methods.

- Minimal Distortion: Laser welding produces minimal distortion, reducing the need for post-welding rework or correction.

- Versatility: Laser welders can join a wide range of materials, including metals, alloys, plastics, and even dissimilar materials.

- Non-Contact Process: Laser welding is a non-contact process, minimizing the risk of contamination or damage to the workpiece.

Factors Affecting the Cost of a Laser Welder

Several factors influence the cost of a laser welder. Understanding these factors can help you determine the appropriate budget for your welding requirements.

Power and Capability

The power and capability of a laser welder significantly impact its cost. Higher power laser welders are capable of handling thicker materials and performing deeper welds. They are generally more expensive than lower power models.

Brand and Reputation

The brand and reputation of the laser welder manufacturer also play a role in its cost. Well-established and reputable brands often come with a premium price tag due to their quality, reliability, and customer support.

New or Used Equipment

The choice between purchasing a new or used laser welder affects the cost. While used equipment may be more affordable initially, it may have higher maintenance or repair costs in the long run. New laser welders often come with warranties and support, ensuring peace of mind and reliable performance.

Additional Features

Certain additional features can enhance the functionality of a laser welder, but they may also increase its cost. These features include automation capabilities, advanced control systems, integrated cameras, and software compatibility.

Warranty and Support

The warranty and support provided by the manufacturer can influence the cost of a laser welder. Longer warranty periods and comprehensive support services may result in a higher upfront cost but can offer better protection and assistance throughout the lifespan of the equipment.

Consumables and Maintenance Costs

Consider the ongoing costs associated with laser welders, such as consumables and maintenance. Consumables include items like protective lenses, nozzles, and gases required for the welding process. Regular maintenance and servicing are essential for ensuring the optimal performance and longevity of the equipment.

Cost Range for Laser Welders

The cost of a laser welder can vary significantly based on the factors mentioned above. Entry-level laser welders suitable for small-scale applications can range from $5,000 to $15,000. Mid-range models with increased power and capabilities may cost between $15,000 and $50,000. High-end industrial-grade laser welders, designed for heavy-duty operations, can exceed $100,000.

It’s important to note that these are approximate price ranges, and specific models may deviate from this general outline. Prices may also vary depending on the country, supplier, and other market factors.

Choosing the Right Laser Welder for Your Needs

When selecting a laser welder, it’s crucial to assess your specific requirements and budget. Consider factors such as the materials you’ll be working with, the required power and precision, the expected workload, and the long-term costs of ownership.

Additionally, consult with reputable suppliers or industry experts who can provide valuable guidance in choosing the right laser welder for your needs.

Conclusion

Laser welders offer numerous benefits in terms of precision, speed, and versatility. While the cost of a laser welder varies based on factors like power, brand, new or used equipment, additional features, warranty, and maintenance costs, it’s essential to make an informed decision based on your specific requirements.

By carefully considering these factors and consulting with experts, you can find a laser welder that meets your needs and delivers optimal results for your welding projects. To explore more options and gather detailed information, you can get more insights from industry-leading suppliers and manufacturers.

FAQs

Are laser welders suitable for all types of materials?

Laser welders are versatile and can work with a wide range of materials, including metals, alloys, plastics, and dissimilar materials.

What is the expected lifespan of a laser welder?

The lifespan of a laser welder depends on various factors, including usage, maintenance, and quality. With proper care, a laser welder can last for several years.

Do laser welders require special training to operate?

Operating a laser welder requires specialized training to ensure safety and optimal results. Training programs are available to help users gain the necessary skills.

What are the ongoing costs associated with laser welders?

Ongoing costs include consumables like protective lenses and gases, as well as maintenance and servicing to keep the laser welder in top condition.

Can I upgrade the capabilities of a laser welder in the future?

Depending on the model and manufacturer, some laser welders may offer upgrade options to enhance capabilities or add new features. It’s advisable to check with the manufacturer for upgrade possibilities.

![10 Best Bags for Nurses | Personal Recommendation [2023] 4 Best Bags For Nurses Reviews in 2021](https://knowworldnow.com/wp-content/uploads/2022/12/Best-Bags-For-Nurses-Reviews-in-2021.webp)

![F95Zone Games - The Ultimate Guide for 2021 [F95Z Guide] 8 F95Zone Games](https://knowworldnow.com/wp-content/uploads/2021/07/ArTtW5LrK3b-z-0-y-637f48d86203817a9042a857.webp)