Have you ever wondered what the unsung hero of your pump’s efficiency is? Cue the cartridge seal – not just equipment but a cornerstone for keeping things running smoothly. This vital component is the Gandalf to your Middle-earth, staunchly holding back the flood (or, in this case, the fluid) and safeguarding your pump’s integrity.

Here, we’ll embark on a journey to demystify these guardians of the pump realm, setting you up with the wisdom to choose your very own seal with confidence. Ready to become a seal sleuth? Let’s get started.

Understanding Cartridge Seals

A cartridge seal, in essence, is your pump’s knight in shining armor. With an assembly that includes the gland, sleeve, and springs, it’s designed not just to sit tight but to form a formidable barricade against leaks.

Acting as a meticulous gatekeeper, this seal ensures the pumped medium and the outer world remain staunch strangers. Now, while these components may sound like a mundane list, each plays a pivotal role—think of them as the cast of a blockbuster movie, where even the supporting roles are critical to the plot. And just like a blockbuster, a pump’s performance can hinge on the strength and compatibility of these components.

The Impact of the Right Seal

Landing the right seal for your pump is akin to finding the perfect key to a lock—it’s a seamless fit that makes all the difference. When harmony reigns between the seal and pump, expect a performance akin to a symphony orchestra—every part in perfect tune.

But, should the seal be mismatched, it’s like a sudden off-key note that sends shivers down your spine—troublesome leaks and wear-and-tear that lead to a pump’s untimely swan song.

Selecting a seal isn’t just ticking a box; it’s a critical decision that can mean the difference between a pump humming along or gasping for air. It’s about giving your pump the best defense against the siege of operational woes.

Types of Cartridge Seals

Like choosing a character in a role-playing game, picking a cartridge seal requires knowing the types at your disposal. First up, the single spring seal – a versatile pick that’s a jack-of-all-trades for general applications.

Then there’s the dual seal, the dynamic duo designed for higher security in containing hazardous fluids. And let’s not forget the mixer seal, tailored for the DJ of the pump world – mixers and agitators.

Each type has its stage, its spotlight where it performs best. Single seals often lead to less aggressive environments, while dual counterparts brace for more challenging conditions.

Mixer seals, with their unique design, groove perfectly in applications where movement isn’t just linear. Knowing your players helps cast the right star for your pump’s performance.

Factors to Consider When Choosing a Seal

Choosing a seal without considering material compatibility is like wearing flip-flops in a snowstorm – utterly out of place. The material must suit the fluid to prevent a chemical mismatch that could corrode your pump’s inner workings. It’s a puzzle where every piece must fit precisely.

Next, weigh in on operational conditions like a judge at a talent show. High temperatures and pressures, along with the corrosive nature of the environment, can push a seal to its limits. It’s about matching the seal’s endurance with the harsh realities of its workplace.

Size and fit are the Cinderella moments for seals – if it fits perfectly, it’s meant to be. An improper size can be the pea under the mattress – a small annoyance causing significant discomfort. It’s vital to measure meticulously for a harmonious fit.

Lastly, consider reliability and maintenance as if choosing a trusty sidekick. Some seals boast features that make them more reliable and easier to maintain, ensuring your operations run like a well-rehearsed play, minimizing unexpected intermissions.

Installation and Maintenance

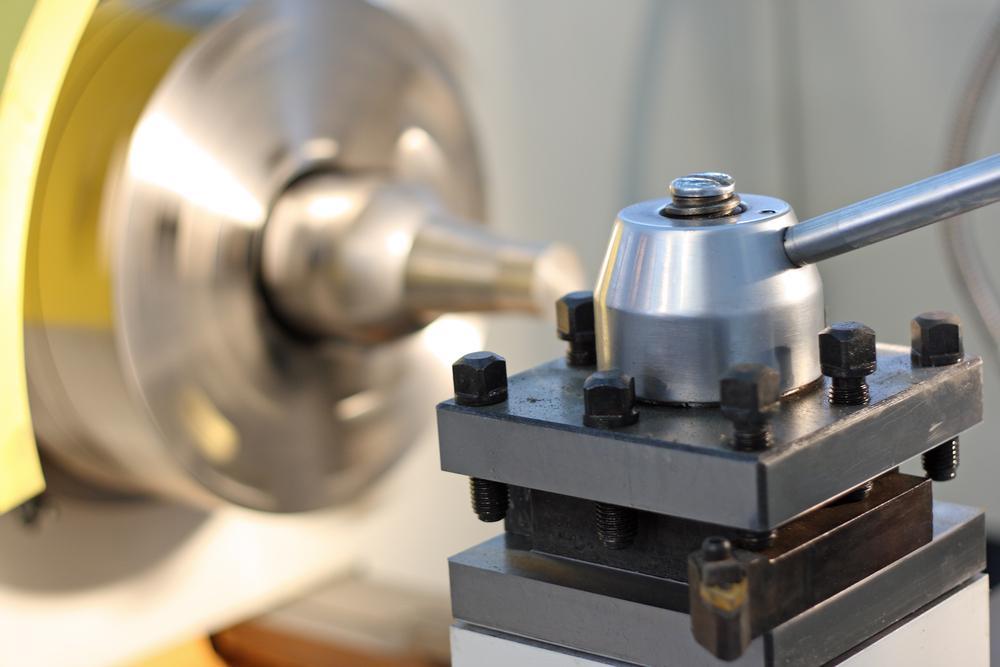

Installing Goulds cartridge seals is no throw-it-together Sunday dinner; it’s a gourmet meal that demands your attention to detail. Make sure surfaces are cleaner than a whistle — any grit or grime can lead to the seal’s early retirement.

And for maintenance? Treat it like your prized garden; regular check-ins and tender care ensure a flourish rather than a wither. Keep a vigilant watch for wear and tear; catching a minor issue early can be the stitch in time that saves nine, keeping your seal running smoother than a jazz tune.

Considerations for Purchasing

When it comes to cartridge seals, it’s similar to assembling your fantasy football team: you want the greatest players without any prejudices clouding your judgment.

However, it is not just about the name on the back; look for the data that are important, such as quality certifications and performance under duress. These are the characteristics of quality, not just a brand’s promise, that will help your pump’s defense stand up on fourths and inches.

Sealing the Deal: Your Guide to Pump Longevity

Wrapping things up and finding the right cartridge seal is more than ticking a box; it’s ensuring your pump has a long and prosperous journey ahead. It’s about piecing together the knowledge you’ve gathered, like the final scene of a mystery novel.

With an understanding of the various seals, how to install them, and the beat of their maintenance rhythm, you’re ready to choose wisely. And if you are pondering options or tangled in the technicalities, remember, experts are out there, just a question away, prepared to help you tailor the perfect fit for your pump’s unique needs.

![10 Best Bags for Nurses | Personal Recommendation [2023] 5 Best Bags For Nurses Reviews in 2021](https://knowworldnow.com/wp-content/uploads/2022/12/Best-Bags-For-Nurses-Reviews-in-2021.webp)

![F95Zone Games - The Ultimate Guide for 2021 [F95Z Guide] 9 F95Zone Games](https://knowworldnow.com/wp-content/uploads/2021/07/ArTtW5LrK3b-z-0-y-637f48d86203817a9042a857.webp)