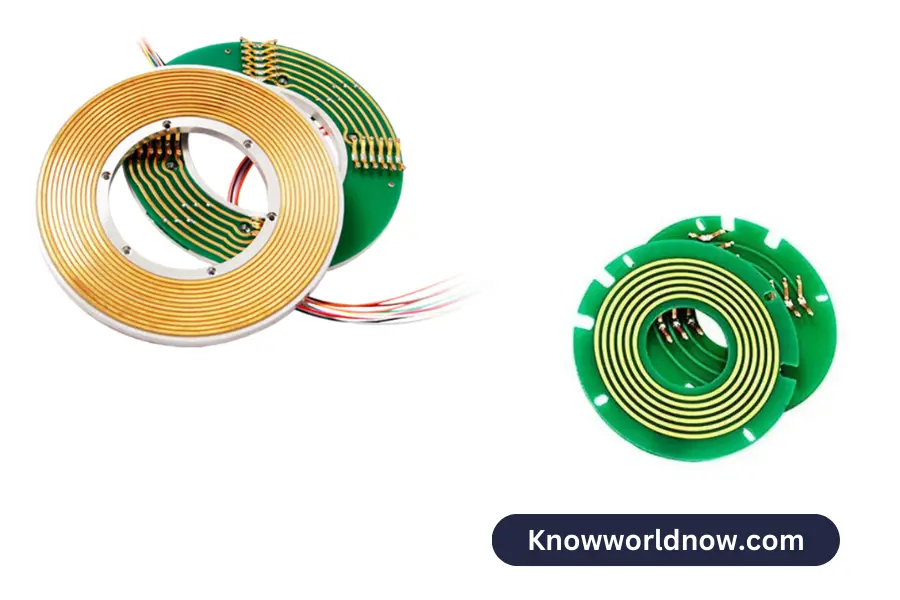

Slip ring connectors play a vital role in enabling the transmission of signals and power between stationary and rotating components in various industries.

Slip ring connectors play a vital role in enabling the transmission of signals and power between stationary and rotating components in various industries. These connectors provide a seamless connection that allows for continuous rotation without compromising electrical conductivity.

In this article, we will explore the concept of a DIY slip ring connector, specifically focusing on building your own PCB slip ring. PCB slip rings offer several advantages, especially in compact electrical systems, and building one yourself allows for customization and cost-effectiveness.

Understanding PCB Slip Ring

PCB slip rings, also known as printed circuit board slip rings, are slip ring connectors that integrate the conductive tracks directly onto a printed circuit board. This design offers several unique features and benefits. The advantages of using PCB slip rings over traditional slip ring designs include:

Compact Size: PCB slip rings are highly compact due to the integration of conductive tracks on a printed circuit board. This makes them ideal for applications where space is limited, such as robotics, drones, and small machinery.

Customization: PCB slip rings can be easily customized to meet specific design requirements. The layout of the conductive tracks can be tailored to accommodate different signals and power requirements, allowing for optimal performance in a particular application.

Cost-effectiveness: Building a DIY PCB slip ring can be more cost-effective compared to purchasing pre-manufactured options. By sourcing the necessary materials and components, you can save on costs while still achieving a high-quality slip ring connector.

PCB slip rings find applications in a wide range of industries, including aerospace, robotics, automation, and medical devices. They are commonly used in applications where space constraints and customization options are critical factors.

Building a DIY PCB Slip Ring Connector

Building your own PCB slip ring connector offers several advantages, including customization and cost-effectiveness. Here’s a step-by-step guide to help you build your DIY PCB slip ring connector:

Step 1: Gather the Required Materials and Tools

To build a DIY PCB slip ring connector, you will need the following materials and tools:

- A printed circuit board (PCB)

- Conductive tracks or copper tape

- Slip rings

- Soldering iron

- Solder wire

- Flux

- Wire cutters

- Wire strippers

- Electrical tape

Step 2: Design the PCB Layout

Using a computer-aided design (CAD) software or a PCB design tool, create the layout for your PCB slip ring connector. Consider the number of conductive tracks required for your specific application and arrange them accordingly. Ensure that the layout allows for easy soldering and proper connections.

Step 3: Prepare the PCB

Using the PCB layout you designed, create or order the PCB. If you are creating it yourself, follow standard PCB fabrication techniques such as etching or milling. Ensure that the PCB size and shape fit the requirements of your application.

Step 4: Apply the Conductive Tracks

Apply the conductive tracks or copper tape onto the PCB. The conductive tracks should align with the layout you designed. Carefully solder the tracks onto the PCB, ensuring a secure and reliable connection. Use flux and solder wire to achieve clean and strong solder joints.

Step 5: Mount the Slip Rings

Attach the slip rings to the PCB, aligning them with the conductive tracks. Use a soldering iron to solder the slip rings onto the PCB. Be careful not to apply excessive heat to prevent damage to the slip rings. Ensure that the slip rings are securely attached and have good electrical contact with the conductive tracks.

Step 6: Connect the Wires

Strip the insulation from the wire ends and solder them to the slip rings. Use wire cutters and strippers to prepare the wires properly. Connect the appropriate wires to the corresponding slip ring terminals, following the electrical design of your application. Use electrical tape to insulate the connections and provide additional protection.

Step 7: Test the Functionality

Once the DIY PCB slip ring connector is assembled, it is crucial to test its functionality. Use a multimeter to measure the continuity and electrical conductivity of the slip rings and conductive tracks. Verify that the signals and power are transmitted smoothly through the slip ring connector.

Testing and Troubleshooting

Testing the functionality of a DIY PCB slip ring connector is essential to ensure its proper operation. Conduct the following tests to verify signal transmission and identify potential issues:

Continuity Test: Use a multimeter to check the continuity of the conductive tracks and slip rings. Ensure that there are no breaks or open circuits.

Signal Integrity Test: Apply signals or power through the slip ring connector and measure the output on the other end. Verify that the transmitted signals or power remain stable and free from significant losses or distortions.

If you encounter any issues during the testing process or experience difficulties with signal transmission, consider the following troubleshooting techniques:

Double-check the solder joints: Inspect the solder joints between the slip rings, conductive tracks, and wires. Ensure that they are properly soldered and have good electrical contact.

Verify the alignment: Check the alignment between the slip rings and conductive tracks. Misalignment can cause signal disruptions or losses.

Inspect for shorts or breaks: Look for any short circuits or breaks in the conductive tracks. Use a magnifying glass if necessary to identify small faults that may be affecting signal transmission.

Re-solder if necessary: If you find any faulty connections, re-solder them using proper soldering techniques. Ensure that the joints are clean, secure, and have good conductivity.

Conclusion

Building your own DIY PCB slip ring connector offers customization and cost-effectiveness, allowing you to create a tailored solution for seamless electrical connections in rotating systems.

By understanding the benefits of PCB slip rings, following a step-by-step assembly process, and conducting thorough testing, you can successfully build a DIY PCB slip ring connector.

Remember to consider the specific requirements of your application and evaluate the feasibility of a DIY approach based on your available resources and expertise. Embrace your creativity and enjoy the satisfaction of building a functional slip ring connector that meets your unique needs.

![10 Best Bags for Nurses | Personal Recommendation [2023] 5 Best Bags For Nurses Reviews in 2021](https://knowworldnow.com/wp-content/uploads/2022/12/Best-Bags-For-Nurses-Reviews-in-2021.webp)

![F95Zone Games - The Ultimate Guide for 2021 [F95Z Guide] 9 F95Zone Games](https://knowworldnow.com/wp-content/uploads/2021/07/ArTtW5LrK3b-z-0-y-637f48d86203817a9042a857.webp)